Caiyi Cylinder UV Printer

Caiyi Cylinder UV Printer

- Detail

- Parameters

- Review

CY-UV2513 Cylinder

Double working stations, 4 rows on each station

Designed for cylinder printing

4 Advantages of Caiyi Cylinder UV Printer

● Perfect solution to seam jointing problems

Achieves 360° rotation printing without blind spots. Every time a part of the pattern is printed, the clamping roller will automatically rotate to the next blank space for printing. It can perfectly achieve seamless jointing in the unit of 0.01mm while ensuring high-resolution printing quality

Print W and C simultaneously 360° rotation printing solves the seam jointing Finished confirmed Printing

● No Product Size Restrictions

The printing area can be adjusted according to the actual size of the product, with a maximum of 80mm and a miminum of 10mm, which can be easily printed, making your products free from compatibility issues and achieving diversified production.

10mm 80mm

●Universal printing, unlimited materials

Wide range of applications, any material can be printed to meet the needs of various industries

wood material stone material ceramic material

Glass material metal material acrylic material

PVC Material plastic material leather material

●Loop Printing Doubles the Output

The dual-station printer can print back and forth. While printing at the front or rear station, you can load and unload goods at another station to achieve both printing and placement, which greatly improves production efficiency.

4 Core Technologies of Caiyi Cylinder UV Printer

● Adopts Ricoh G5i Print head

High Resolution: The droplet size of 3.5PL provides the best combination of throughput and print quality for a variety of applications.

High Pixels: Different inkjet solutions can be used according to different printing materials, and the printing colors are accurate, with clear layers and even transitions.

Intelligent Maintenance: When the printer is not working, the head will automatically flash to keep it moist to avoid clogging caused by ink solidification.

● Diversified Head Configurations

It can be equipped with up to 12 high-performance print heads, which meets customer output while achieving extremely high resolution.

4 rows, white and color 4 rows, white, color and varnish

● Multiple Printing Effects and Features

Relief Printing with Varnish

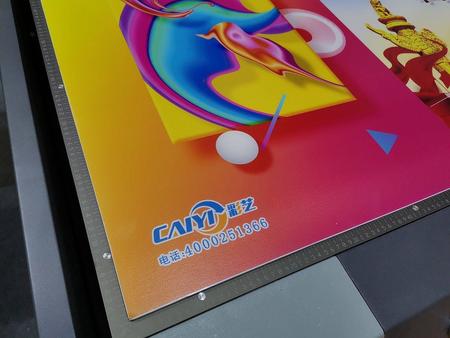

Vibrant colors and durable quality!

Combines white + color, white + color + varnish, color + white + color, and CMYK printing colors to provide high-end results in hundreds of applications.

● Comprehensive Improvements in Speed and Productivity

Three printing modes are available, and the printing width is doubled to help customers complete production and personalized printing services faster.

Mode 1: 1.5mm Mode 2: 3mm Mode 3: 6mm

Technical Featuers

☑ 3.5PL variable ink droplet, high resolution printing

☑ All steel print head with a longer life time and it is corrosion resistant

☑ Imported Linear Motor and Maglev railway for stable operation

☑ Imported screw drive, high precision

☑ Intelligent ink alarm system

☑ Automatic height detecting and positioning system

☑ Independent control of Color and White negative pressure system

Hard Oxidized Sinkhole Vacuum Table with Registration Pins

The Vacuum Table is divided into several vacuum zones. The stronger vacuum avoids the friction between the print head and the media. The table surface hardness reaches HV500-700. It is more scratch-resistant and wear-resistant. The load per square meter is up to 100KG. Meanwhile, the table is equipped with Registration Pins for easier loading of rigid materials. It is very user-friendly.

Through the destructive experiments and long-time test, the Y axis adopts Panasonic Servo System and the PMI Screw Drive Structure System to ensure the high mechanical movement accuracy, durability and the stable performance.

The machine adopts branded water cooling LED uv lamp that complies with the UL standards. The light is environment-friendly, and the lamp has a long life time of 35000 hours. Thanks to the low hear of the light, heat-labile medias are also applicable.

Imported Linear Motor and Maglev Railways, and Metal Raster Tape

For the carriage movement, the machine is equipped with excellent-quality Linear Motor and Maglev Railways, and Metal Raster Tape. Thus, the carriage runs more accurately and steadily without vibration, which in turn makes the printing at a good quality even at high-speed running.

The X-axis gantry is made of 200px*400px aviation aluminum profile, which has high tensile strength and large bearing capacity. It is stable enough and will not deform for long-term use.

Automatic Height Detector

The optimal distance between the head and the media can be adjusted just by one click! This easy and quick way avoids the ink spray and helps the machine delivers good printing quality.

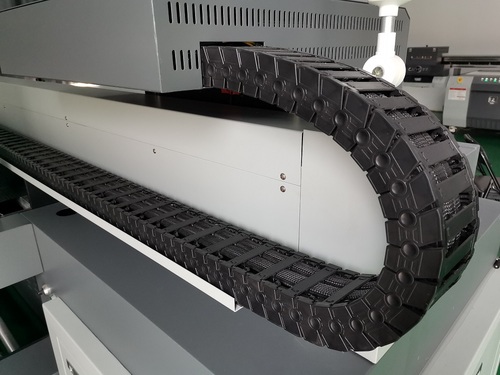

The machine is equipped with good towline. It is wide enough to enable wires long-term work without rubbing against each other, and reduce the noise during the movement.

Anti-Static Device and Crash Sensor

The Anti-Static Device removes the static from the media and perfectly avoids ink spray. The sensitive Crash Sensor on both sides will prevent the print head from being damaged.

The ink Alarm system will give alert via signal light and sound when the ink volume is low. Alert will also be shown in the software interface. The white ink tank has automatic stirring system so that the white print head will not be clogged.

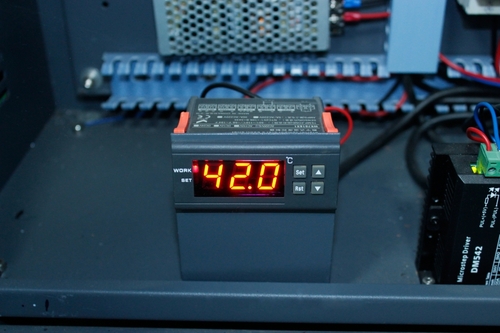

The ink Heating System will heat the ink to an appropriate temperature before it goes into the print head, which makes the ink run more smoothly and avoids the nozzle clogging in cold working environment. Thus, the printing is vivid and bright.

Disk filter

Before going into the print head, the ink will be further filtered by the Disk filter so that the tiny impurities can be filtered out. The printhead will work in a good condition and its life time will be extended.

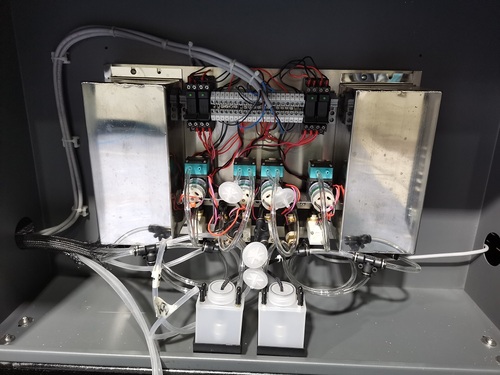

There is an independent valve on each Sub Ink Tank to control the ink flow. When the machine is off, the valve can be closed in order to avoid ink waste.

Independent Ink Purging for White and Color enables purging color and white separately, which ensures smooth ink flow and more stable ink supply when the machine is printing at a high speed.

Negative Pressure System

With the NC pressure display instrument, the machine can do high quality printing at as a high fire frequency as possible to increase the printing speed; With an additional air sub tank to make the change of negative pressure more stable and ensure the stable ink supply at a high-speed nonstop printing.

Panasonic Servo System

Adpots Japanese Panasonic Servo Driver and Servo Motor to realize the closed-loop control of location, velocity and torque, and overcome the out-of-step problem of the stepping motor. They System delivers good performance when running at a high speed and runs steadily when working at a low speed. Also, the System gives timely dynamic response, low running noise, and low heat.

Using 8 cm x 16 cm steel tube and overall welding of the triangle law structure, the base frame is stable and non-deforming. The platform base adopts high-precision gantry milling. It is highly accurate and the flatness error is extremly small.

TECHNICAL PARAMETERS

Model | CY-UV2013 | CY-UV2513 | CY-UV2518 | CY-UV2030 | CY-UV2530 | CY-UV3020 | CY-UV2540 | CY-UV3040 | CY-UV3050 |

Machine Dimesnsion | L: 2.15m | L: 2.15m | L: 2.75m | L: 3.90m | L: 3.90m | L: 3.00m | L: 4.90m | L: 4.90m | L: 5.90m |

W: 3.93m | W: 4.43m | W: 4.43m | W: 3.93m | W: 4.43m | W: 4.93m | W: 4.43m | W: 4.93m | W: 4.93m | |

H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | H: 1.40m | |

Machine Weight | 900kg | 1000kg | 1100kg | 1200kg | 1300kg | 1200kg | 1400kg | 1500kg | 1600kg |

Printing Size | 2.0 x 1.25m | 2.5 x 1.25m | 2.5 x 1.8m | 2.0 x 3.0m | 2.5 x 3.0m | 3.0 x 2.0m | 2.5 x 4.0m | 3.0 x 4.0m | 3.0 x 5.0m |

| Prinitng Speed | 200pcs/h | ||||||||

Cylinder's Max Diameter | 10~80mm (Customized Diameter is Acceptable) | ||||||||

Ink drop Size | Ricoh Gen5i: 3.5PL | ||||||||

Color Configuration | K C M Y W Varnish | ||||||||

Printing Resolution | 720 x 2400 dpi | ||||||||

Ink | Imported UV Ink | ||||||||

Curing Method | Water Cooling LED UV Lamp | ||||||||

Rip Software | Photo Print | ||||||||

Operation System | Win 7 (x64), Win 10 (x64) | ||||||||

Color Control | International ICC standard with adjusting function for profiles and density | ||||||||

Image Format | TIFF, JPEG, CMX, AI, PSD, PS, PDF, EPS | ||||||||

Power Supply | Single Phase AC 220V, 50/60Hz, 14A, 3KW | ||||||||

Environment Requirement | Recommended Humidity: 30%~60% Relative humidity; Recommended Temperature: 15℃~30℃ | ||||||||

Data Interface | USB 3.0 / LAN cable | ||||||||

Printing Medias | Various cylinders | ||||||||

Video Demonstration